Working in conjunction with your planners, we develop the best possible solution from the technical and economic points of view, and assist with installation planning – from the inlet to the outlet of the powerhouse.

Our standard turbines are of a modular design and, can be quickly adapted to the on-site circumstances.

Using the latest tools, we not only design turbines with a 3D drawing program, but can also carry out flow simulations and strength calculations should the situation require changes to be made. In our company, we have specialists in all areas who can ensure that you are well looked after, from installation planning and design right through to plant completion. You can rest assured that you will have access to an expert contact throughout the entire process.

Naturally, providing support after the plant has been built is also important to us.

Do you have a problem or do you need spare parts or consumables (fat, oil, …)? If so, please call our Service Department (see contacts).

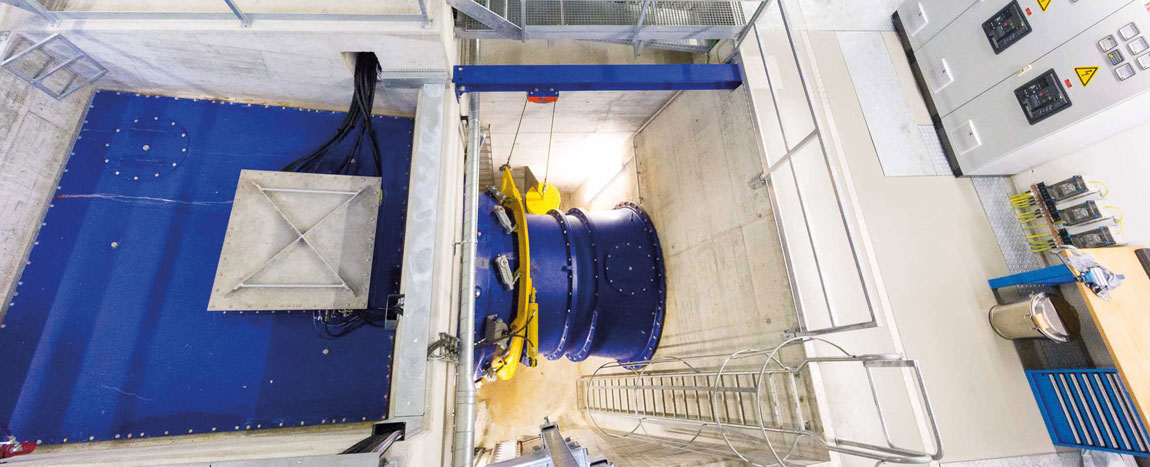

Advantages of Kaplan turbines

They are particularly suitable for high flow rates and low and medium heads.

Double-regulated Kaplan turbines have the following features:

- compact dimensions

- high partial load efficiency

- high peak efficiency

- particularly suitable for sites with fluctuating heads

- specifically high rotational speed (high throughput, small transmission ratios)

Their advantages over Francis and flow turbines are:

- smaller dimensions of hydroelectric generating set and structure with the same degree of expansion – or higher throughput with the same structural dimensions

- much better partial load efficiency

- a rotational speed that is several times higher

- higher annual energy given the structural dimensions

Besides taking into consideration self-evident demands such as high efficiency and long service life, the HSI concept has the following features:

A extremely compact, easy to install and low-maintenance design along with easy accessibility and exchangeability of wearing parts.

The guide vane apparatus is adjusted out of the water (external regulation) and is therefore virtually maintenance-free. The main bearings are designed as grease- or oil-lubricated bearings.

When it comes to the rpm transmission ratio, we prefer modern, low-noise, high-performance flat belts with an efficiency of over 96%, or direct-coupled generators. In this case, we prefer to use a permanent magnet synchronous generator.